Product offensive at Blue Fire GmbH

8. October 2021

Fine dust separation only half the battle

21. June 2024

If we now act urgently and retrofit the 11 million furnaces in the German market with catalytic converters, we will create potential for climate change. All these furnaces are operated with biomass or fossil fuels and always produce CO. Biomass - i.e. wood and woody fuels - release CO2 during combustion, just like fossil fuels. However, the biomass has bound this CO2 from the atmosphere during its growth, so that one speaks of CO2-neutral combustion. The combustion of fossil fuels, on the other hand, releases CO2 that has been formed over millions of years.

In both cases, the release of CO2 harms the climate.

In addition, every combustion process produces CO and releases it into the atmosphere.

CO is not a greenhouse gas. However, it is referred to as an indirect greenhouse gas. However, CO exerts a complex indirect effect in the atmosphere and thus has an influence on the greenhouse gases CH4 and CO2. Basically, the emission of CO reduces the oxidation capacity or oxidising power of the atmosphere. This effect can increase the greenhouse gases CH4 and CO2. This effect contributes to climate change.

Therefore, if CO emissions are reduced, there is a higher oxidation capacity available in the atmosphere for the greenhouse gases CH4 and CO2. The temperature increase of the atmosphere can be reduced by CO reduction.

Compared to CH4 and CO2, CO is very easy to reduce by oxidation with oxygen.

Oxidation catalysts such as those developed and marketed by Blue Fire GmbH make use of this effect.

These catalysts have been specially developed for emissions from wood firing systems. The catalytic coating containing precious metals ensures that the CO molecules react with O2 on their way to the chimney and form CO2 even in the already cooled flue gas.

In the process, however, wood combustion never releases more CO2 than the tree has bound from the ambient air during its growth. The Blue Fire oxidation catalysts are capable of reducing 50% of the CO emissions. This is achieved even if the legally required bypass of 20 cm2 area is provided on the catalytic converter. By using baffles and influencing the exhaust gas flow, it is possible to flow through and use the Blue Fire catalytic converters in a very targeted manner.

In 2019, 3,060,000 t of CO were emitted into the atmosphere in Germany. The largest polluter is motor vehicle traffic. However, emissions from individual room furnaces also contribute their share to CO emissions. In 2019, this amounts to 537,880 t CO per year from individual room furnaces in Germany. Of these, 11 million are operated in Germany.

The limit value of the 2nd stage of the 1st BImSchV is 1250 mg CO per standard cubic metre of flue gas. Many installed furnaces do not yet comply with this limit, but their CO emissions are significantly higher.

The CO reduction through a Blue Fire catalytic converter is 50% despite the mandatory bypass. In Germany alone, the use of Blue Fire catalysts in wood-fired boilers could save 286,940 t of CO emissions per year, which are not released into the atmosphere.

When CO and VOC are emitted, the photochemical cycle of NO-NO2 is disturbed and O3 (ozone) is formed. Ozone is a greenhouse gas and is partly responsible for climate change.

The other chemical processes that take place near the ground and in the higher air layers are very complex and they are based on an equilibrium. If this balance is disturbed, the entire atmospheric chemical structure changes and there are effects on humans and the environment. The hole in the ozone layer, the greenhouse effect and also the formation of acid rain can be traced back to the disturbance of this equilibrium.

We are all called upon to do our utmost to stop climate change and achieve the global warming targets set in Europe. Such simple measures as the use of a catalytic converter in a single-room fireplace can already reduce a considerable proportion of CO emissions, and at the same time the consumer does not have to do without the CO2-neutral and cosy warmth from wood. The additional costs for a catalytic converter integrated into a combustion system are very manageable. As a rule, such catalytic converters cost well under €100 each.

Catalyst technology has been known for a very long time and is well mastered. We all know it from its use in motor vehicles.

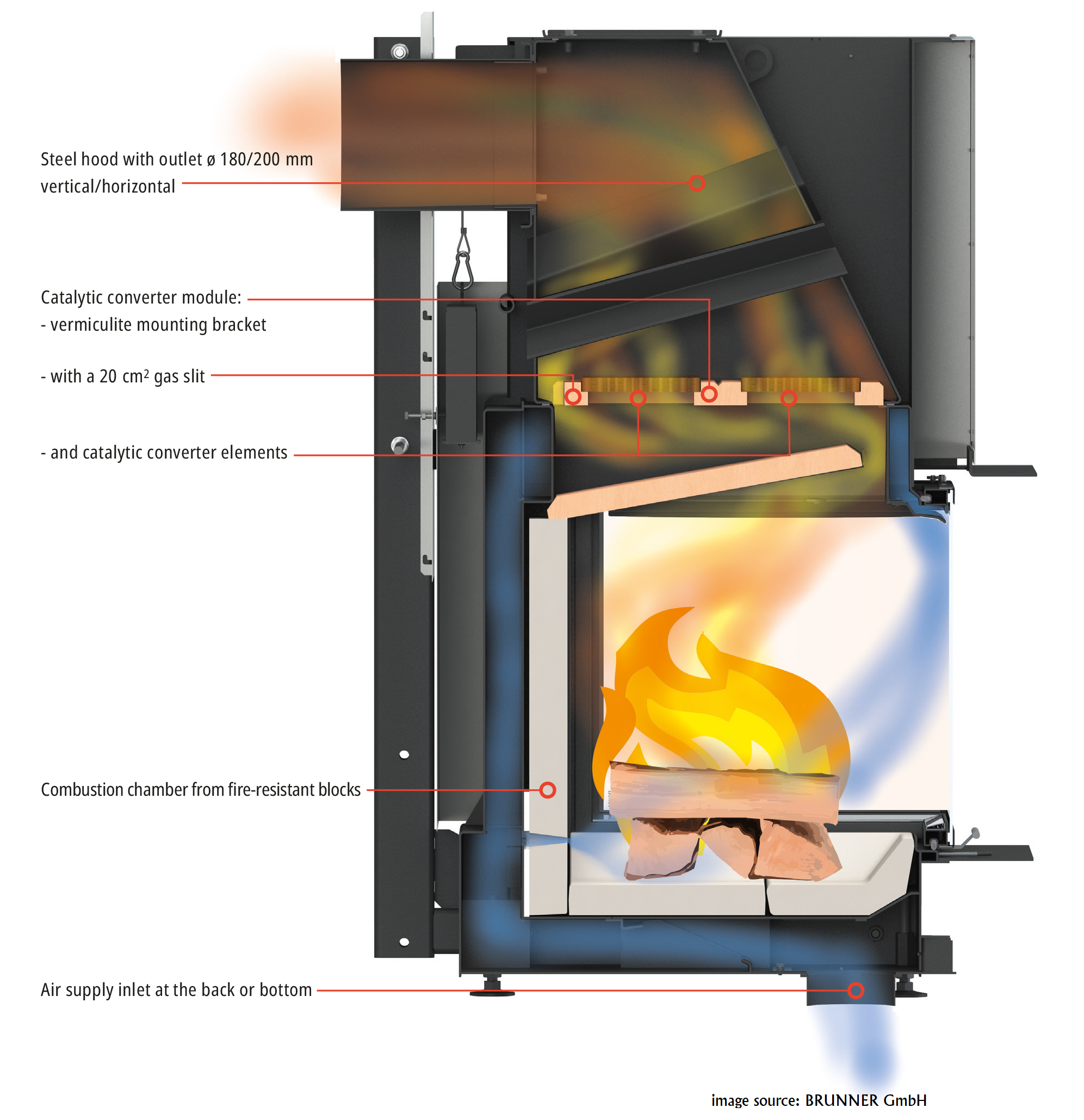

However, there are specially adapted catalytic converters for wood-fired systems, as the exhaust gas is composed differently than in an internal combustion engine. In addition, an engine can convey the exhaust gases through very fine-cell catalytic converters with high pressures of up to 3 bar. However, wood-burning systems usually operate with natural draught and only 12 Pa negative pressure, which is only 0.00012 bar. The porous structure of such catalysts for wood firing systems is therefore also matched to the flue gas back pressure, so that these catalysts cause only a very low pressure loss in the flue gas system.

In new appliances, the catalytic converters can be very easily integrated into the upper part of the combustion chamber. From our point of view, innovative concepts even look like installing the catalytic converters in a box above the combustion chamber that can be opened from the installation room to ensure easy accessibility for cleaning and service.

Don't hesitate and take action to protect our climate. Talk to your specialist stove dealer about wood fires with integrated catalytic converters. Use the best available technology to enjoy the warmth of the wood fire in a CO2-neutral way.