Noble metal-free catalysts compared to catalysts containing noble metals – A question of recycling

8. October 2021

Act now and create potential for climate change by retrofitting catalytic converters

8. October 2021

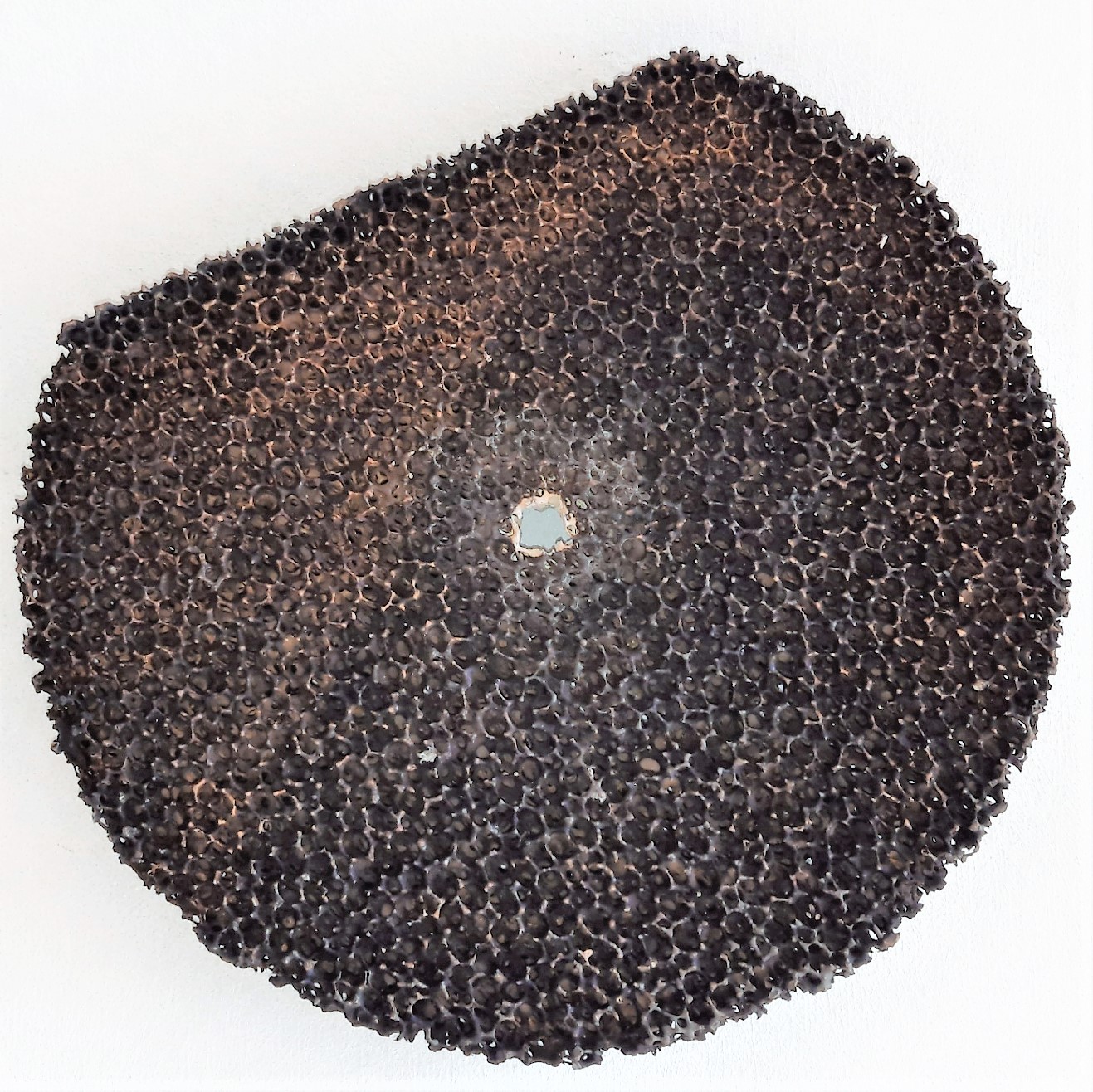

Blue Fire GmbH has taken advantage of the time in the pandemic and prepared itself for the coming heating season. The standard sponge ceramic catalysts with the well-known catalytic coatings COLD, MEDIUM and HOT are available from stock. In addition to the standard dimensions of 155 mm x 120 mm x 18 mm, 2 further dimensions have been added as standard sizes. These are: 280 mm x 165 mm x 18 mm and 240 mm x 155 mm x 18 mm. These catalysts are also available from stock with only very short delivery times.

The sponge ceramic catalytic converters can be integrated into almost any combustion chamber due to the small effective length of only 18 mm. The pressure loss is low at 0.5-1 Pa. Nevertheless, a strong deflection of the exhaust gases takes place in the sponge structure, which leads to many contacts of the exhaust gas with the catalytic surface and produces very good emission reductions.

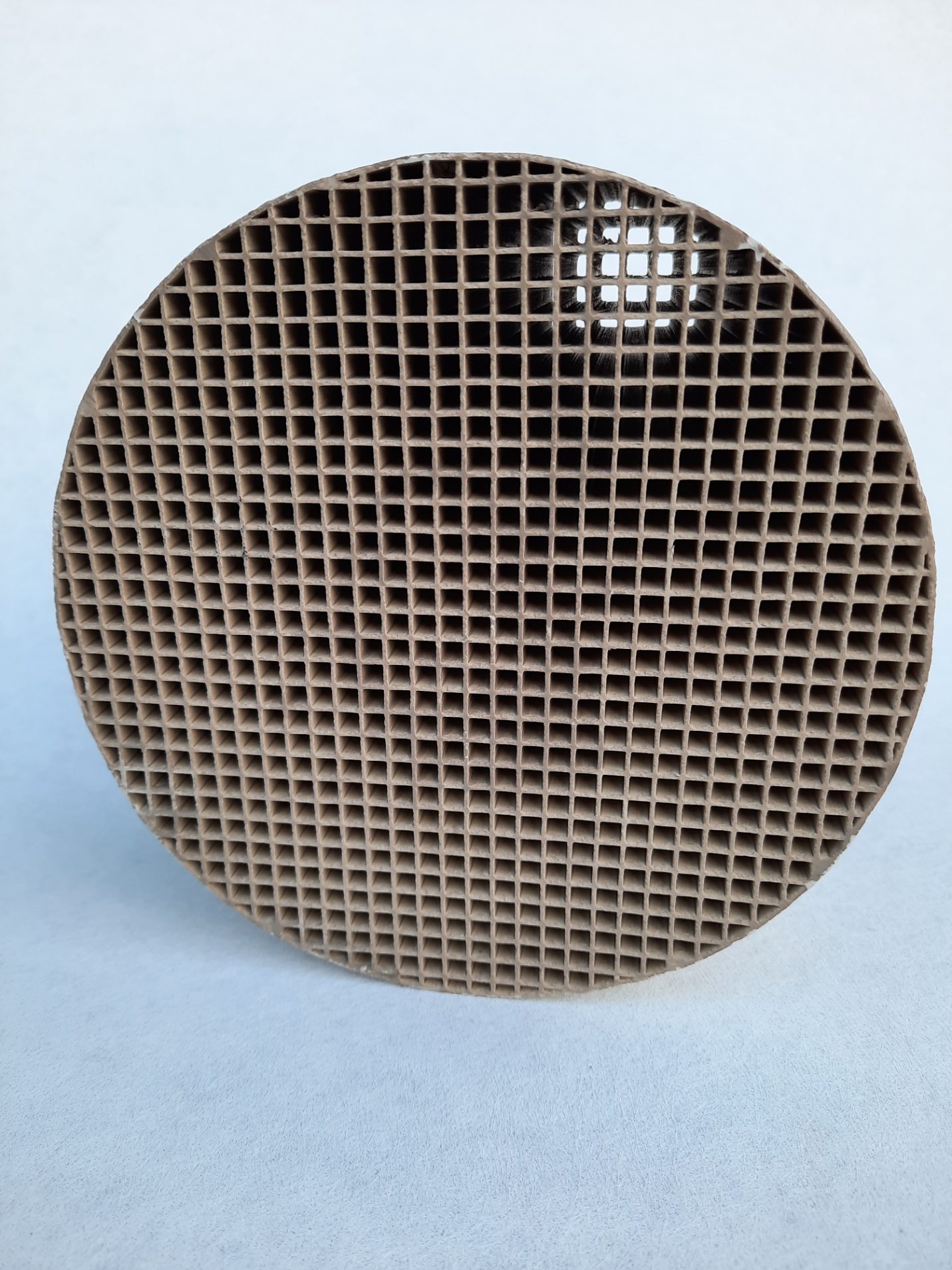

The product range is now complemented by ceramic honeycomb catalysts made of aluminium oxide. These ceramic honeycombs are available with round and square outer dimensions. Cell sizes from 30 - 100 cpsi are available for the wood combustion industry. The construction length is 50 mm as standard, but can be customised.

In addition, bypass sections on the ceramic honeycomb body are possible according to customer requirements.

For the honeycomb body with Ø150 mm, the bypass in the form of a circular segment bend section is 26 mm.

A new, very effective catalytic coating has been developed for the ceramic honeycomb catalysts. It is called VOC because it achieves very good reduction rates for VOC emissions.

The same catalytic coating was prepared for application on metal winding substrates.

The metal winding substrates are manufactured in-house. They consist of very thin foils and have a cellularity of 100 cpsi for the wood combustion industry. All metal winding substrates are bounded by a welded sheet metal ring. Sample catalysts with dimensions Ø120 mm x 50 mm are available from stock.

The metal-wound catalysts are characterised by a very high surface area combined with low pressure loss. Due to the good metallic heat conduction, they reach light-off temperature earlier than comparable ceramic honeycomb catalysts.

Both ceramic honeycomb and metal wound catalysts operate with laminar flow. They work due to the construction length and the adapted dimensions of the cells. In addition, Blue Fire GmbH has added ceramic Pall ring catalysts to its product range. The ceramic Pall rings have an outer diameter of 25 mm and an overall length of 25 mm. The wall thickness is 3 mm. Here, too, we apply the newly developed VOC coating to the base material aluminium oxide.

The Pallring catalysts can be used in a regular arrangement or in bulk. When used in bulk, the exhaust gases are deflected more strongly, which results in an increased pressure loss. Metal supports for the arrangement of Pall ring catalysts or grid containers for the use of poured Pall ring catalysts can also be supplied by Blue Fire. The outer dimensions of the metal supports can be adapted to the requirements of your combustion chamber. The prescribed bypass can be integrated into the metal support. With the expansion of the product range, Blue Fire GmbH offers a wide range of catalysts that have been specially adapted to the requirements of the wood combustion industry in terms of catalytic coating and carrier systems.

If you are interested, we look forward to contacting you.