CO is an indirect greenhouse gas – CO reduction with Blue Fire catalysts

4. October 2021

Product offensive at Blue Fire GmbH

8. October 2021Catalysts are used in many products and the technology is well known and mastered.

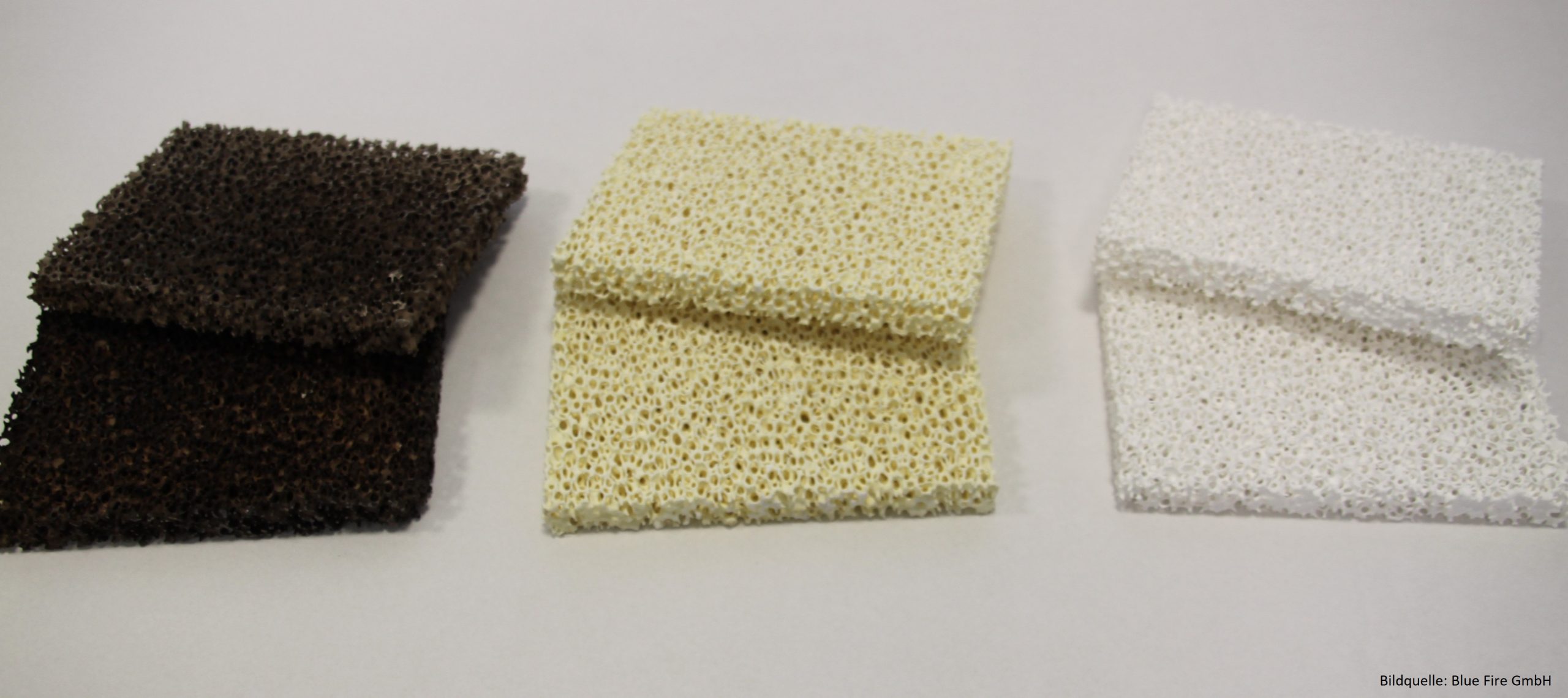

They often work as oxidation catalysts in exhaust systems of vehicles, combined heat and power units, gas engines, fireplace and pellet stoves, in fireplace inserts, tiled stoves, log boilers, wood chip and also pellet boilers and the like. They are subject to large temperature fluctuations during the time of use, ranging from room temperature to over 800°C. Catalytic converters can have a wide variety of support systems made of ceramic or metal, which in turn have a wide variety of structures. However, catalytic converters are always designed in such a way that the very thin catalytic coating adheres firmly to the support system and can withstand the enormous temperature gradients without damage.

Emissions from single room furnaces are mainly dust, carbon monoxide (CO) and organic carbonaceous compounds (OGC). For all 3 emissions, legislation provides for limit values in the relevant standards and regulations. Different standards apply depending on the type of individual room furnace and the fuel used. The limit values for immissions are regulated by the 1st BImSchV with the limit values to be related to the application.

Catalytic converters are needed to catalytically reduce CO emissions from wood firing systems.

CO is always reduced by oxidation with oxygen (O2). CO is oxidised to CO2 by reaction with oxygen. In the combustion chamber of a wood burner, this reaction takes place below the flame baffle, where the temperature level is high enough for such oxidation. However, the flue gases quickly cool down on their way to the flue pipe. The oxidation of the CO with oxygen can no longer take place.

This is where the Blue Fire catalyst comes in. The catalytic converter is flown through by the emission-rich wood exhaust gases. There is also a proportion of oxygen in the flue gas due to the supply of combustion air. Through contact of the CO-containing exhaust gases with the catalytic surface, the activation energy of the CO molecule is reduced and it is again able to react with oxygen despite the already cooled temperature. The catalyst thus provides another possibility for CO oxidation, which would no longer take place without the catalyst due to the exhaust gas temperature being too low.

Temperature is an important parameter for the operation of catalysts. Each catalyst has a characteristic start-up temperature, also called the light-off temperature, above which 50% of the catalytic activity is detectable. In catalytic converters with precious metal doping, the light-off temperature can be reached more quickly and at a lower temperature level.

The further the exhaust gas has already cooled down, the sooner the catalytic coating has to be doped with precious metals such as platinum, palladium or rhodium. The precious metal doping ensures that the CO molecules allow the reaction with oxygen despite the already low exhaust gas temperature. It is important, however, that the precious metals are distributed very evenly on the catalyst surface in a very small form - nano-sized. The more evenly the precious metals are distributed on the surface, the easier it is for the exhaust gas flowing through the catalytic converter to come into contact with a precious metal cell embedded in the surface.

The brief contact between the exhaust gas and the catalytic surface reduces the activation energy and the CO or OGC emissions are again able to react with oxygen. The desired oxidation of CO to CO2 or of CnHm to CO2 and shorter CnHm chains occurs.

The selection of the precious metals and their mixing ratio are just as important as the very even distribution of the precious metals on the catalyst surface. There are precious metals that can be used particularly well for emission reduction of the CO and OGC emissions mentioned. However, there are also other precious metals that can be used for the accumulation of oxygen on the catalyst surface. Others are more suitable for use in petrol or diesel exhaust. Still other precious metals and their mixtures are used in catalysts for gas or biogas emissions.

The experience of the catalyst manufacturer comes into play when selecting the precious metals and the mixing ratios.

The oxidation that takes place at the catalytic converter using the ambient oxygen only occurs at correspondingly high temperatures, which are necessary for the reaction. In the combustion chamber in the post-combustion zone below the flame impingement plate, the emission-rich exhaust gases sweep over the flame tip. With the addition of secondary air, the emissions react to form the reaction products described above. As the flue gases continue their journey through the wood burner, they cool down quite quickly and no further reaction takes place between CO or OGC and oxygen.

If one wants to dispense with the use of precious metals and use catalysts free of precious metals, this is only at the expense of the light-off temperature. Precious metal-free catalysts start to become active at a higher temperature.

This is made possible by a coating of mixed metal oxides developed for wood combustion applications. This coating also achieves good conversion rates for CO and OGC reduction without further use of precious metals, but requires a higher temperature for activation.

Precious metal-free catalytic coatings, such as the Blue Fire mixed metal oxide coating, also promote a reaction of CO with oxygen. However, due to the absence of precious metals, this only occurs after a somewhat longer operating time and also only at a higher temperature level. Because of their composition, precious metal-free catalysts can therefore be used directly in the combustion chamber. One thus benefits from the higher temperature level, e.g. when mounting the catalyst on the flame impingement plate. By using them in the higher temperature range of the exhaust gas, one can compensate for the sluggish response behaviour of the non-precious metal catalysts.

The advantage of non-precious metal catalytic converters is that they can do without the cost-intensive and rare precious metals altogether, thus conserving these resources. They consist from mixtures of different metal oxides, all of which have good availability. Through targeted research and development, mixtures can be worked out that also have very good catalytic effects against CO and OGC. The precious metal-free Blue Fire catalyst, for example, is already being used in multi-stage catalyst systems. The non-precious metal catalyst is mounted directly in the combustion chamber below the flame impingement plate. Its task is to reduce CO and dust from the hot portion of the exhaust gas. The catalytic converter of the second stage is integrated into the exhaust gas path behind the flame baffle plate. There, the exhaust gas temperatures have already cooled down to such an extent that a catalytic converter containing precious metals is used to further reduce CO and OGC. Such systems can reduce CO emissions to measured values that are close to the detection limit.

Recycling plays a very important role, especially for catalysts containing precious metals. By specifically returning the catalysts containing precious metals to the manufacturer, the precious metals can be recovered to a very high degree (>95%). For this purpose, the catalysts are shredded and homogenised by a grinding process. The precious metals can then be recovered from the molten mass by heating.

Emission Partner GmbH & Co. KG, the parent company of Blue Fire GmbH, has already introduced a nationwide recycling system for used catalytic converters, which is to be rolled out to Blue Fire GmbH's customer base.

The non-precious metal catalysts should also be recycled, as the metal oxides used can also be recovered to a high degree. In both cases, recycling serves environmental protection and the conservation of resources. This ultimately leads to stable raw material prices, from which the furnace manufacturer and the furnace user benefit in the end.

The recycling of raw materials concerns us all. Blue Fire has prepared the way for this and makes this service available to the stove industry.